Membrane Nitrogen Gas Generator / Plant |

Membrane Nitrogen Gas Generator

- Delivery Time 30 Days

- Main Domestic Market All India

- Minimum Order Quantity 1

- Supply Ability 10 Per Month

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

Membrane Nitrogen Gas Generator

- Delivery Time 30 Days

- Main Domestic Market All India

- Minimum Order Quantity 1

- Supply Ability 10 Per Month

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

Membrane Nitrogen Gas Generator Plant

- Delivery Time 30 Days

- Main Domestic Market All India

- Minimum Order Quantity 1

- Payment Terms Cash in Advance (CID)

- Supply Ability 10 Per Month

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

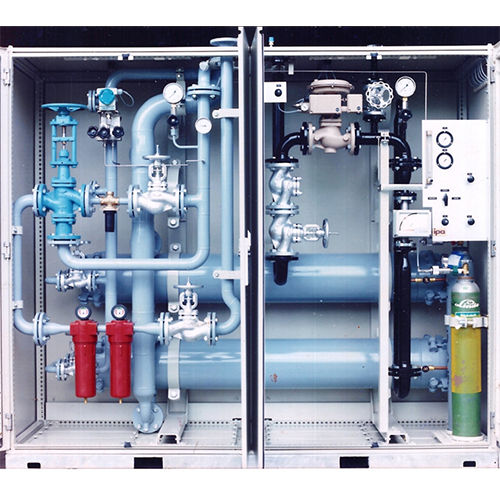

Enjoy unlimited supply of high purity nitrogen gas with our Membrane Nitrogen Gas Generator Plant. Made with premium quality stainless steel, this gas generator plant is designed to provide reliable and cost-effective solutions for a variety of industrial applications. Its compact size and customizable dimensions make it easy to install in any work environment. The sleek blue design adds a touch of elegance to its functionality, making it an ideal choice for businesses of all sizes.

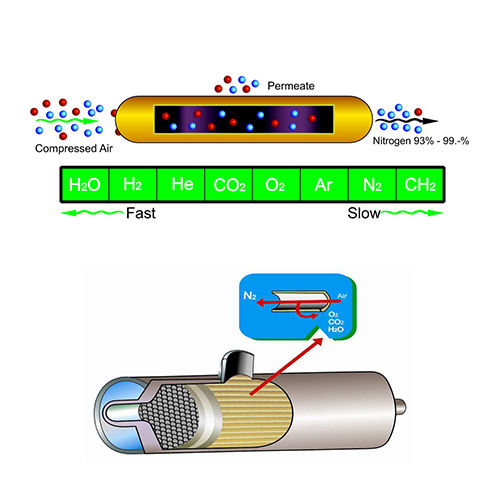

Principle

The rate of permeation of different gases are different. Membranes separate gases by the principle of selective permeation across the membranes wall. For nitrogen polymeric membranes, the rate of permeation of each gas is determined by its solubility in the nitrogen membrane material, and the rate of diffusion through the molecular free volume in the nitrogen membrane wall. Gases that exhibit high solubility in the nitrogen membranes, and gases that are small in molecular size, permeate faster than larger, less soluble gases.

Fast gases permeate through the nitrogen membrane wall more readily than slow gases, thus separating the original gas mixture into two streams. The purity of the desired streams can be adjusted by changing the operating conditions.

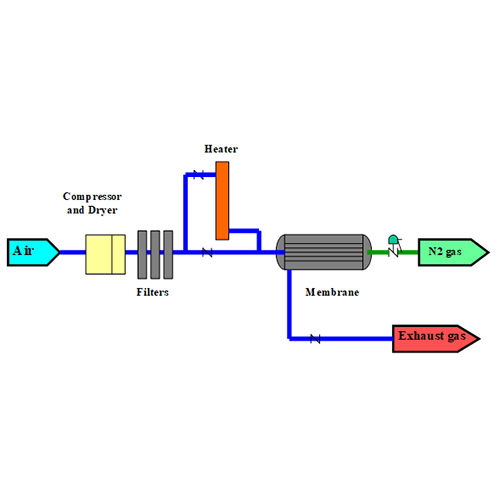

Process

Membrane processes rely on the fact that under pressure, gases tend to be permeated through the wall of the hollow fibre membranes. Faster gases permeate faster than slower gases. When a treated compressed air passed through the membrane, water, carbon dioxide and oxygen permeates and vented to atmosphere where as Nitrogen comes out in the main stream as the product gas.. It is a continuous process. No depressurization or regeneration is required.

Specifications

|

Capacity |

1 to 10000 Nm3/hr |

|

Purity |

93 to 99.9 % ( Higher purity by down stream Purification system) |

|

Pressure |

9 to 25 Bar (g) standard . ( Higher Pressure on request) |

|

Dew Point |

(-) 40 deg C to (-) 80 deg C |

Applications

- Nitrogen gas is being used in many industries

- for a variety of applications.

- Oil & Gas

- Marine

- Chemical & Petrochemical

- Pharmaceutical

- Food & Beverages

- Metal & Metallurgical

- Mining

- Laboratories, R&D Centers

- Electronics

- Fertilizer

- Many more