Refrigeration Air Dryer

Product Details:

Refrigeration Air Dryer Price And Quantity

- 1 Unit

Refrigeration Air Dryer Trade Information

- 10 Unit Per Month

- 30 Days

- All India

Product Description

Air Gas Dryer

In an ideal compressed air system air dyer is one of the most critical and important equipment. In general industry selects a dryer from the standard model of a dryer of any particular brand without knowing actual dryness ( Dew point) required for their application. As a result of this, sometimes over designed dyer will unnecessarily cost more in terms of its capital cost, operation and maintenance cost and sometimes less designed dryer will lead to frequent application, process and instruments failure,

Calorie-HNT specializes in following type of air dryers.

A. Refrigeration dryer

B. Regenerative Adsorption dryer

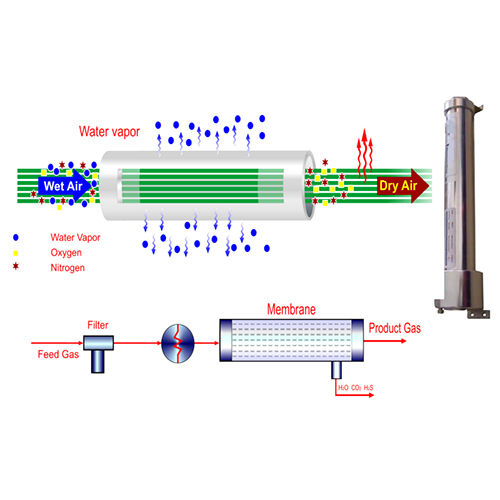

C. Membrane dryer

Regenerative Adsorption Type is further classified as

1. Heatless dryer

2. Internally Heated dryer

3. Externally Heated dryer

4. No loss Split Flow dryer

5. Heat of Compression dryer

REFRIGERATION DRYER

Principle

The temperature of the compressed air is brought down to 2-3 deg C in an heat exchanger through a refrigeration cycle. As a result of cooling moisture present in the compressed air gets condensed and knocked out in a moisture separator. Dry air having a pressure dew point (+) 3 deg C is available for use.

Process

The process is continuous and non cyclic. The saturated compressed air enters into a heat exchanger where it is partially cooled by the chilled air coming out from the moisture separator. This partially cooled air is further cooled down to (+) 3 deg C in the evaporator of the refrigeration cycle. A complete refrigeration systems which consists of a compressor, condenser, expansion valve and evaporator ensures the continuous cooling of the incoming compressed air. The systems is automatic with all relevant safety interlocks and proper instrumentation. The moisture of the outgoing compressed air is knocked down in a moisture separator and drained out through and automatic drain valve.

Specifications

- Capacity - 100 to 15,000 Nm3/hr

- Pressure - 5 to 16 Bar (g) standard . ( Higher Pressure on demand)

- Pr.Dew Point - (+) 3 deg C

It is very important for proper selection of air dryer. Selection depends upon many factors like capacity, pressure, Temperature, dew point, location, type of air compressor and mainly the application. A improper selection may cost in terms of capital investment and operational cost. Hence it is recommended to specify the complete details to Calarie.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free