Regenerative Adsorption Dryer

Product Details:

Regenerative Adsorption Dryer Price And Quantity

- 1 Unit

Regenerative Adsorption Dryer Trade Information

- 10 Unit Per Month

- 30 Days

- All India

Product Description

Looking for an efficient and reliable air dryer for your industrial needs? Look no further than our Regenerative Adsorption Dryer! Designed to remove moisture from compressed air, this dryer is available in multiple sizes to fit your specific requirements. It operates on a voltage range of 220-440 and is proudly made in India. Our dryer comes with a warranty for your peace of mind and is designed in a sleek white color to seamlessly blend into your workspace. As a trusted distributor, manufacturer, service provider, supplier, and trader, we ensure the highest quality and performance of our products.

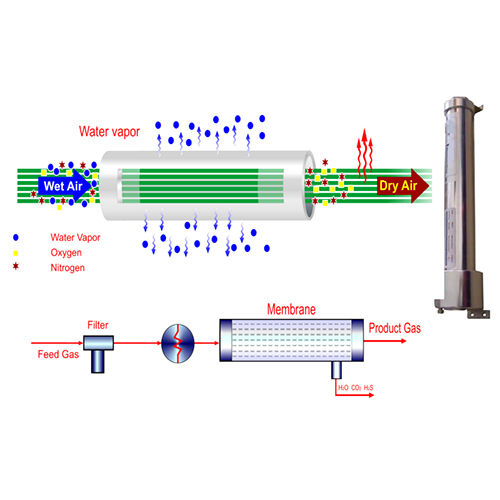

Principle

The adsorption type dryers are also termed as desiccant dryers. Theses type of dryers are usually used where low dew point in the range (-) 40 deg C - (-) 80 deg C is required. A desiccant is used for the adsorption of moisture. It is twin column and cyclic process. When one column is in adsorption mode, the other is in regeneration mode. The regeneration of desiccant is done by heating the desiccant followed by subsequent cooling.

HEATLESS DRYER

The principle is the same as explained above but in this case the desiccant is regenerated by small quantity of dry air itself. There is no heating is required, hence it is termed as Heatless. The dry air required for the regeneration is basically a loss of dry compressed air which is in tune of 7-12% for a consistent dew point of (-) 40 deg C. This loss is termed as purge loss. Since there is loss of dry air , it is only recommended for a smaller capacities

Specifications

- Capacity - 5 to 1000 Nm3/hr

- Pressure - 5 to 16 Bar (g) standard . ( Higher Pressure on demand)

- Pr.Dew Point - (-) 40 deg C to (-) 73 deg C

INTERNALLY HEATED DRYER

This type of dryer has electrical heater embedded inside the desiccant columns. These dryers are most suitable for the application where very low dew point in the range of (-) 60 - (-) 80 deg C is required. Regeneration of the desiccant is done by heating of the desiccant and purging with the small quantity of the dry air.

Specifications

- Capacity - 50 to 8,000 Nm3/hr

- Pressure - 5 to 16 Bar (g) standard . ( Higher Pressure on demand)

- Pr.Dew Point - (-) 40 deg C to (-) 80 deg C

EXTERNALLY HEATED DRYER

This type of dryer has electrical heater installed outside the desiccant columns. These dryers are most suitable for larger capacities beyond 500 Nm3/hr and for the application where dew point i(-) 40 deg C is enough. Regeneration of the desiccant is done by heating of the desiccant and purging with the atmospheric air from an external air blower. There is NO LOSS of compressed air.

Specifications

- Capacity - 500 to 15,000 Nm3/hr

- Pressure - 5 to 16 Bar (g) standard . ( Higher Pressure on demand)

- Pr.Dew Point - (-) 40 deg C

NO LOSS SPLIT FLOW DRYER

This type of dryer similar to externally heated type but there is no external blower is required. The main stream of the compressed air is divided into two streams. The main stream enters one of the drying column and gets dried while a small portion of second stream is routed trough an external heater and enters into the second column for regeneration and after regeneration it combines with the main stream. The reaeration is done in a closed loop. In this dryer one regeneration cooler and one after cooler is used. These dryers are most ideal for larger capacities beyond 500 Nm3/hr and for the application where dew point i(-) 40 deg C is enough.

Specifications

- Capacity - 500 to 15,000 Nm3/hr

- Pressure - 5 to 16 Bar (g) standard . ( Higher Pressure on demand)

- Pr.Dew Point - (-) 40 deg C to (-) 80 deg C

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free